PG is a digital solution for visual worker guidance in production. It supports employees step by step in assembly, testing, and rework processes, prevents errors, and automatically documents all work steps. This ensures quality, traceability, and stable processes—even in the face of skilled labor shortages and high product variability.

Digital worker guidance for error-free production processes

Errors, liability risks, and data gaps in production?

Learn how consistent data collection eliminates these risks and ensures your quality in the long term.

Why a digital worker guidance is essential

Increasing product variety, a shortage of skilled workers, and high quality requirements are posing new challenges for production. A digital worker guidance ensures clear processes, reduces the workload on employees, and creates transparency for each individual work step.

“The PG worker guidance achieves demonstrable results in everyday production. Customers report significantly reduced training times, noticeably less rework, and measurable time savings per employee and shift. As a result, the introduction of a worker guidance system often pays for itself after only a short time.”

Matthias SalzbergerProduct Owner PG

100

80

75

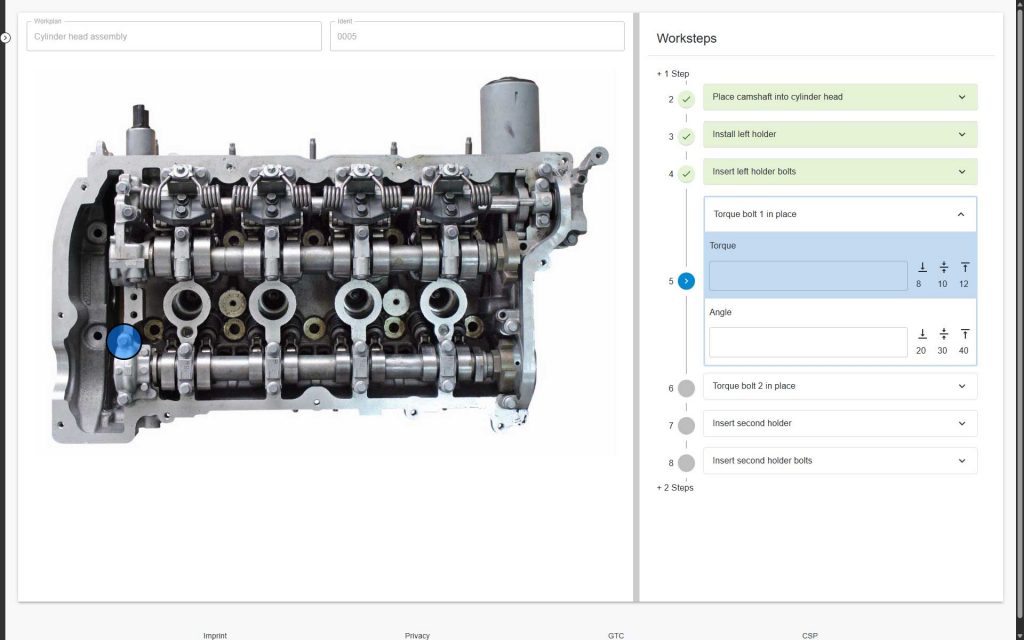

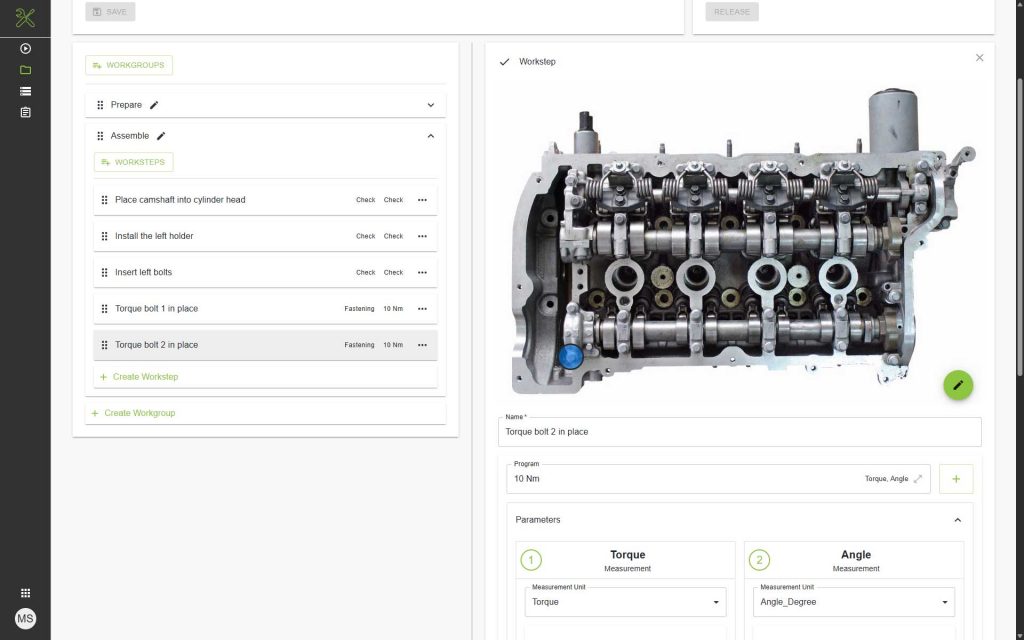

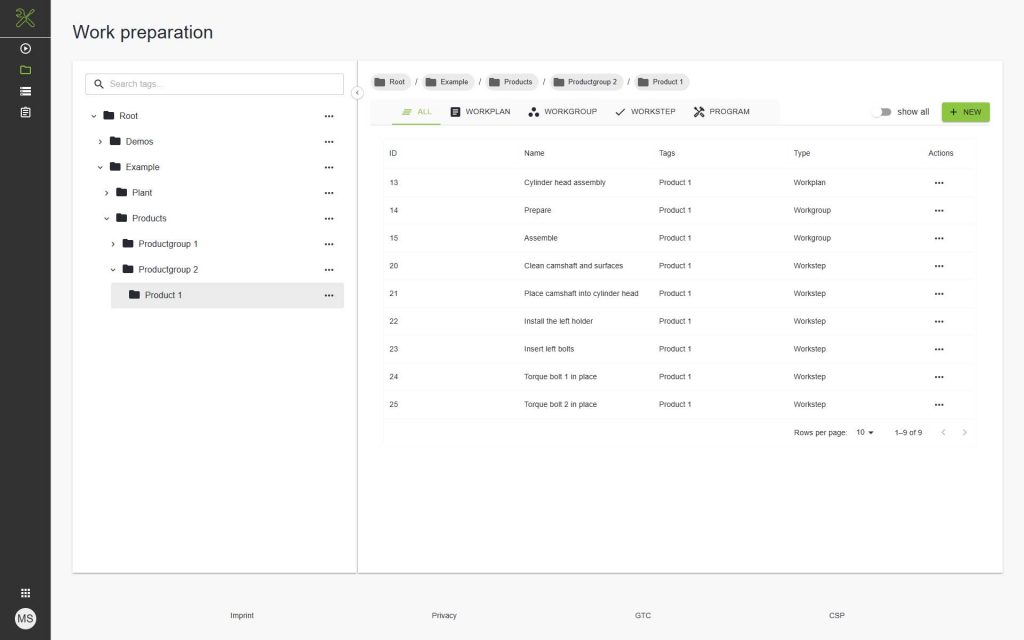

Simple. Visual. Intuitive: PG Web

Why companies choose the PG digital worker guidance

Error prevention through guided processes

PG guides employees step by step through the process and ensures correct, complete execution. Rework, rejects, and complaints are measurably reduced.

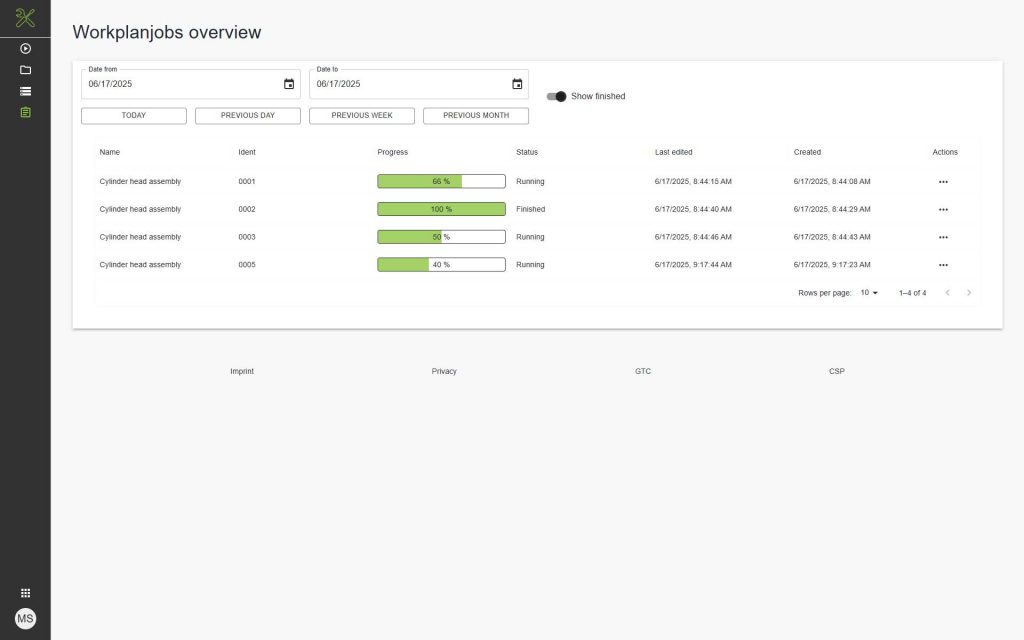

Complete, audit-proof documentation

All process data is automatically recorded and documented in an audit-proof manner. Audits and liability issues can be verified at any time.

Productive in hours – not in weeks

New employees quickly become productive with PG. Visual worker guidance reduces training costs and makes knowledge immediately available.

Stable processes even with a wide range of variants

PG standardizes processes even with a high degree of variety and ensures consistent quality.

No dependence on manufacturers or tools

PG is completely manufacturer-independent and integrates seamlessly into existing tool, MES, and IT systems.

AI that really saves time – PG Q·AI

With PG Q·AI, existing documents such as Word, PowerPoint, or PDF files are automatically converted into digital, structured work instructions.

Leading companies rely on our PG worker guidance

4.9/5

AI-supported process optimization with PG Q·AI

PG Q·AI automates the creation of digital work instructions directly from existing documents such as PDF, Word, or PowerPoint. The content is converted into structured, visual SOPs and can be used immediately in the worker assistance system.

Efficiency gains in work preparation

PG Q·AI significantly reduces the manual effort involved in creating and maintaining work instructions.

Consistent quality in production

Uniform formats ensure reproducible results and stable processes.

Why paper work instructions are no longer sufficient in modern production

Worker guidance vs. paper work instructions

Unlike paper-based work instructions, a digital worker guidance is always up to date, adapts to product variants, and automatically documents all work steps. This results in stable, reproducible processes, even in highly varied or safety-critical production environments.

Legal certainty through complete documentation

Worker guidance & product liability

A digital worker guidance ensures that defined processes are followed precisely and that this can be verified at any time. Each work step is automatically recorded, checked, and documented in an audit-proof manner. In the event of a complaint or liability claim, the worker assistance system provides decisive proof that all relevant process steps were carried out correctly.

Worker guidance in everyday production

Worker guidance for employee support

A modern worker guidance makes production knowledge available at all times and reduces dependence on the experience of individual employees. New colleagues become productive more quickly, while experienced specialists are relieved of some of their workload and can concentrate on value-adding activities.

Worker guidance PG –

proven in many industries

The PG worker guidance is used in numerous industries: from the automotive sector and mechanical engineering to aerospace. Wherever precise assembly processes, consistent documentation, and traceability are required, PG ensures error-free operations.

Assembly

Assistance and automatic documentation

Inspection

Visual guidance and tracking

Rework

Error detection and efficient correction

Revision (Service)

Support for service and maintenance work

CUSTOMER STORIES

Leading companies rely on PG

Ready for error-free production with PG?

With our digital worker assistance system, you can make your production more efficient, safer and of higher quality – without any lengthy training. Get started now and experience how easy error-free production can be.

FAQ

Is PG compatible with my existing hardware?

Yes, PG is manufacturer-independent and can be integrated with various hardware and software systems.

Can PG also be used offline?

Yes, PG can be used in isolated production environments without a constant Internet connection.

How long does the implementation of PG take?

The implementation period depends on the individual requirements, but can often be completed in just a few weeks.

Is it possible to adapt to specific processes?

Yes, PG is flexible and can be individually adapted to your production processes.

Which manufacturers are compatible with the PG worker guidance?

The PG worker guidance is completely manufacturer-independent and compatible with a wide range of leading tool, measurement, and automation systems. These include, among others:

- Atlas Copco

- Desoutter

- Cleco

- Gedore

- Bosch Rexroth

- Stahlwille

- ELIAS

- ITH

- HST

- Keyence

- Hytorc

- MB-RAD

- Ingersoll Rand

- Sturtevant Richmont

- AcraDyne

- Stanley

- many more